Graphene’s remarkable properties could revolutionize display manufacturing by enhancing electrical conductivity and thermal management. This leads to faster response times, improved refresh rates, and lightweight, durable products. Advantages like eco-friendliness and cost-efficiency align with modern sustainability goals. Current applications include touchscreens and flexible displays, while future innovations promise ultra-thin, high-resolution screens. However, challenges like production costs and material compatibility must be addressed. Discover how these factors shape the future of display technology.

The Unique Properties of Graphene

Graphene, often hailed as a “wonder material,” boasts a suite of unique properties that set it apart from traditional materials. Its exceptional electrical conductivity allows for rapid charge transport, making it an ideal candidate for enhancing electronic components. This characteristic not only improves device efficiency but also enables miniaturization without sacrificing performance. Additionally, graphene’s remarkable thermal management capabilities facilitate effective heat dissipation, essential for maintaining peak operating temperatures in electronic devices. By integrating graphene into display technologies, you can leverage these properties to create lighter, more efficient screens with enhanced responsiveness. As you explore the potential of graphene, consider how its unique attributes could redefine freedom in design and functionality, pushing the boundaries of what’s possible in display manufacturing.

Advantages of Graphene in Display Technology

As the demand for high-performance displays continues to grow, incorporating graphene into display technology offers numerous advantages that can greatly enhance user experience. Graphene’s exceptional electrical conductivity allows for faster response times and improved refresh rates, which translates to smoother visuals. Its lightweight nature considerably reduces materials needed for display fabrication, promoting cost efficiency. In addition, graphene’s durability leads to longer-lasting products, decreasing waste and showcasing a positive sustainability impact. These attributes not only enhance performance but also align with eco-friendly manufacturing practices, catering to a market increasingly focused on sustainability. By embracing graphene, you’re not just investing in better displays; you’re supporting a future that values efficiency and environmental responsibility in technology.

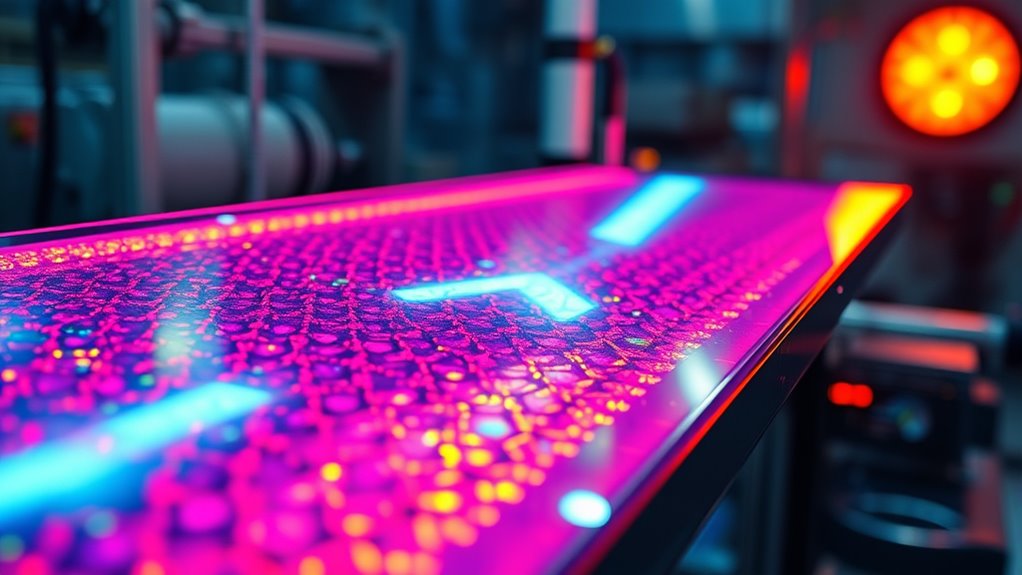

Current Applications of Graphene in Displays

The integration of graphene into display technologies is already making waves across various applications. You’re witnessing its use in touchscreens, where graphene’s exceptional conductivity enhances responsiveness and durability. In OLED displays, graphene applications are being explored to replace traditional materials, improving efficiency and reducing production costs. Flexible displays benefit from graphene’s lightweight and robust properties, allowing for innovative form factors without compromising performance. Additionally, transparent conductive films made from graphene are revolutionizing how displays achieve ideal brightness and clarity. As you explore the world of display technologies, it becomes evident that graphene’s unique characteristics are setting a new standard, paving the way for more advanced, efficient, and versatile displays in the market.

Future Innovations Driven by Graphene

While many current applications of graphene in displays are impressive, the future holds even greater potential for innovation. As you explore future technologies, consider how graphene’s unique properties can enable ultra-thin, flexible displays that maintain high resolution and color fidelity. You’ll likely see advancements in energy-efficient screens, leveraging graphene’s conductivity to reduce power consumption considerably. Additionally, innovative graphene applications could lead to enhanced durability, allowing displays to withstand environmental stressors better than ever before. Imagine lightweight, foldable devices that integrate seamlessly into everyday life, fostering a new era of user experience. With ongoing research, the possibilities are vast, and the next generation of displays could redefine how you interact with technology, making it more accessible and freeing.

Challenges and Considerations for Graphene Integration

Integrating graphene into display manufacturing presents a series of challenges that must be maneuvered to fully harness its potential. You’ll need to address several critical factors, including:

- Cost Factors: The initial investment in graphene production and processing can be substantial.

- Scalability Issues: Developing methods for large-scale graphene production while maintaining quality is essential.

- Material Compatibility: Ensuring graphene’s compatibility with existing materials and processes is a significant hurdle.

- Regulatory Concerns: Maneuvering safety and environmental regulations related to graphene usage can complicate integration efforts.

Frequently Asked Questions

What Is Graphene Made From?

You’re exploring graphene, which consists of a single layer of carbon atoms arranged in a two-dimensional lattice. Its remarkable properties enable diverse applications, from electronics to materials science, showcasing its potential impact across various industries.

How Is Graphene Produced Commercially?

Imagine weaving a fabric of atoms; that’s how graphene’s produced. Through various graphene synthesis techniques like chemical vapor deposition and liquid-phase exfoliation, industries harness its potential for applications ranging from electronics to energy storage.

What Are the Main Sources of Graphene?

You’ll find graphene primarily sourced from graphite, reduced graphene oxide, and chemical vapor deposition. These sources leverage graphene’s remarkable properties, enabling diverse applications across electronics, energy, and materials science, enhancing performance and functionality in various fields.

Is Graphene Environmentally Friendly?

You might wonder about graphene’s environmental impact. Its applications can promote sustainability, but production methods vary. While some processes are eco-friendly, others may pose risks. Evaluating each aspect’s sustainability is essential for informed decisions.

Can Graphene Be Recycled After Use?

You might wonder if graphene can be recycled after use. Graphene recycling processes are emerging, promoting graphene sustainability. These advancements aim to recover valuable materials, reducing waste and supporting a circular economy for future applications.