Tyre pressure monitors continuously measure air pressure in each tyre, ensuring ideal performance and safety. There are two main types: direct TPMS uses sensors in the tyres for real-time pressure readings, while indirect TPMS infers pressure changes through wheel speed analysis. When pressure drops below preset levels, alerts notify you with visual or audible signals. Maintaining these systems is essential for reliability and safety, and further insights on this topic can enhance your understanding of TPMS functionality.

Understanding Tyre Pressure Monitoring Systems

While you might not think about it often, understanding tyre pressure monitoring systems (TPMS) is essential for maintaining vehicle safety and performance. TPMS plays a critical role in tyre safety by continuously monitoring the air pressure in each tyre. When pressure drops below a certain threshold, the system alerts you, enabling timely intervention. This pressure regulation prevents uneven tyre wear, enhances handling, and improves fuel efficiency. Knowing how TPMS functions empowers you to make informed decisions about your vehicle’s maintenance. By ensuring ideal tyre pressure, you not only prolong the life of your tyres but also contribute to a safer driving experience. Embracing this knowledge allows you to enjoy the freedom of the road with confidence.

Types of Tyre Pressure Monitors

Understanding the different types of tyre pressure monitors (TPMs) can greatly enhance your vehicle’s safety and performance. There are two primary sensor types: direct and indirect. Direct sensors measure the air pressure in each tyre using pressure sensors located within the valve stem. They provide real-time data and can alert you to any pressure drops immediately. Indirect sensors, on the other hand, use monitoring technologies that analyze the rotational speed of the tyres, inferring pressure levels based on changes in wheel circumference. While direct systems offer more accurate readings, indirect systems can be less complex and more cost-effective. Choosing the right TPM can empower you with the information needed to maintain peak tyre health and guarantee a safer driving experience.

Direct vs. Indirect Monitoring

When considering tyre pressure monitoring systems, you’ll encounter two primary methods: direct and indirect monitoring. Direct monitoring employs sensor-based technology to provide real-time pressure readings, while indirect monitoring relies on wheel speed analysis to infer pressure changes. Understanding the accuracy and reliability of each system is essential for maintaining ideal tyre performance.

Sensor-Based Monitoring

Sensor-based monitoring of tyre pressure can be categorized into two primary systems: direct and indirect monitoring. Direct systems utilize advanced sensor technologies mounted on each tyre to measure pressure, providing real-time data and higher monitoring accuracy. In contrast, indirect systems rely on existing wheel speed sensors to infer tyre pressure based on changes in rotation.

- Direct monitoring enhances safety by alerting you immediately to pressure drops.

- Indirect systems are often more cost-effective since they leverage existing hardware.

- Each approach has its pros and cons, affecting overall reliability and responsiveness.

Ultimately, understanding these differences allows you to choose a system that best suits your driving needs and preferences for autonomy.

Wheel Speed Analysis

In vehicle dynamics, wheel speed analysis plays a crucial role in both direct and indirect tyre pressure monitoring systems. In direct systems, sensors measure tyre pressure directly, while indirectly, the system infers pressure changes through wheel rotation data. Here, speed correlation becomes essential; a decrease in a tyre’s pressure leads to a difference in wheel speed compared to others. By analyzing these variations, the system can identify potential issues. You’ll notice that maintaining ideal tyre pressure enhances performance, ensuring that wheel rotation remains balanced. This method offers a unique perspective on how your vehicle’s dynamics can be refined for better handling and fuel efficiency, giving you the freedom to drive confidently, knowing your tyres are in peak condition.

Accuracy and Reliability

Although both direct and indirect tyre pressure monitoring systems aim to guarantee ideal tyre performance, their accuracy and reliability can differ considerably. Direct systems utilize sensors mounted on each tyre, ensuring precise readings and real-time data. Conversely, indirect systems rely on wheel speed analysis, which can be affected by external factors.

- Monitor Calibration: Direct systems require regular calibration to maintain sensor accuracy, ensuring consistent performance.

- Sensor Accuracy: High-quality sensors in direct systems provide detailed pressure readings, reducing the risk of underinflation.

- Environmental Factors: Indirect systems may misinterpret data due to changes in temperature or load, potentially compromising accuracy.

Understanding these differences helps you choose the most suitable monitoring system for your needs.

How Direct TPMS Works

In understanding how Direct TPMS works, you’ll first need to contemplate the sensor installation process, which is critical for accurate performance. These sensors provide real-time pressure monitoring, relaying essential data to your vehicle’s system. When pressure drops below a safe threshold, a warning signal mechanism alerts you, ensuring timely action can be taken.

Sensor Installation Process

Direct Tire Pressure Monitoring Systems (TPMS) rely on sophisticated sensors installed within each tire to continuously assess air pressure levels. The installation process is essential for guaranteeing accurate readings and performance. You’ll want to follow specific installation guidelines to avoid issues down the line.

- Confirm proper sensor calibration before installation to maintain accuracy.

- Use compatible tools and equipment to avoid damaging the sensor.

- Double-check the positioning of the sensor within the tire for ideal performance.

Real-Time Pressure Monitoring

Real-time pressure monitoring is a critical feature of Direct Tire Pressure Monitoring Systems (TPMS), ensuring you receive instant feedback on your tire’s air pressure. These systems use sensors mounted on each tire to continuously measure pressure and detect fluctuations. When the system identifies any deviation from the ideal pressure range, it sends real-time alerts to your vehicle’s dashboard, allowing you to take immediate action. This proactive approach helps prevent issues like blowouts and can enhance fuel efficiency. By maintaining proper tire pressure, you also enjoy improved handling and safety. Understanding how these systems function empowers you to make informed decisions regarding your vehicle’s maintenance, giving you the freedom to drive with confidence.

Warning Signal Mechanism

When tire pressure drops below a predetermined threshold, the warning signal mechanism in a Direct Tire Pressure Monitoring System (TPMS) activates to alert the driver. This activation involves various warning signal types, utilizing distinct alert mechanisms to convey critical information efficiently.

- Visual Alerts: Dashboard lights illuminate, typically featuring a tire icon, providing immediate visual feedback.

- Audible Signals: Beeping sounds accompany visual alerts, ensuring that the driver doesn’t miss the warning.

- Vibration Feedback: In some systems, steering wheel vibrations may signal a drop in pressure, enhancing driver awareness.

How Indirect TPMS Works

Although indirect tire pressure monitoring systems (TPMS) may not offer the same level of precision as their direct counterparts, they effectively utilize existing vehicle sensors to monitor tire performance. By employing the antilock braking system (ABS) wheel speed sensors, these systems perform indirect monitoring of tire pressure. When a tire loses pressure, its rolling radius decreases, leading to different wheel speeds compared to properly inflated tires. This discrepancy triggers pressure alerts to inform you of potential issues. While indirect TPMS can’t provide specific pressure readings, it serves as a reliable early warning system, helping you maintain ideal tire health and ensuring a safer driving experience. Staying vigilant about these alerts allows you the freedom to drive with confidence.

Sensors and Their Role in TPMS

Sensors play a pivotal role in both direct and indirect tire pressure monitoring systems (TPMS). Understanding sensor types and their placement is essential for effective monitoring.

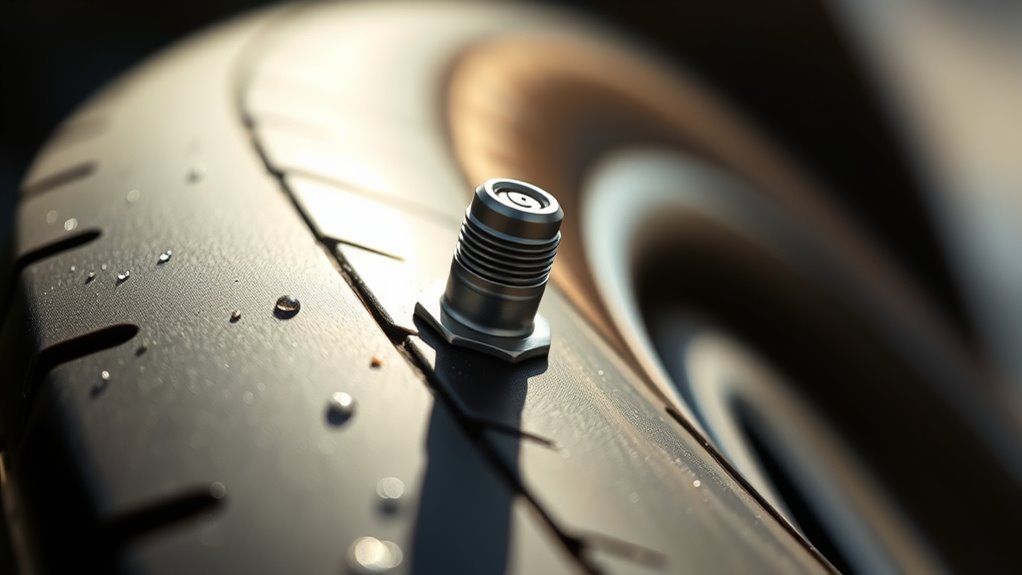

- Direct TPMS Sensors: These are typically located inside the tire and measure pressure directly, providing real-time data.

- Indirect TPMS Sensors: Found within the vehicle’s ABS, they monitor wheel speed and infer pressure changes indirectly.

- Sensor Placement Considerations: Proper placement enhances accuracy; direct sensors are mounted on the valve stem, while indirect sensors rely on wheel rotation data.

Detecting Pressure Changes

Detecting pressure changes in tires is vital for maintaining ideal vehicle performance and safety. Tire Pressure Monitoring Systems (TPMS) utilize sensors that continuously measure tire pressure, alerting you to any deviations from preset pressure thresholds. These sensors are calibrated to guarantee accuracy, responding to even minor fluctuations. When tire pressure drops below the defined threshold, the system triggers a warning, allowing you to take immediate action. Regular sensor calibration is essential, as environmental factors and tire wear can affect readings over time. By confirming your TPMS is functioning correctly, you can prevent potential hazards and enhance your driving experience. Ultimately, understanding how pressure changes are detected empowers you to maintain control over your vehicle’s performance and safety.

Benefits of Using Tyre Pressure Monitors

Using Tire Pressure Monitors offers numerous advantages that enhance both vehicle safety and efficiency. By providing real-time data on tire pressure, you can maintain ideal conditions while driving, which ultimately leads to:

- Enhanced Safety: Accurate tire pressure reduces the risk of blowouts and improves handling.

- Improved Fuel Efficiency: Properly inflated tires minimize rolling resistance, allowing your vehicle to consume less fuel.

- Prolonged Tire Life: Monitoring pressure helps prevent uneven wear, extending the lifespan of your tires.

These benefits not only contribute to safer driving experiences but also promote a more economical approach to vehicle maintenance. By embracing this technology, you’re taking proactive steps toward ensuring both your safety and your vehicle’s ideal performance on the road.

Common Issues With TPMS

Many drivers rely on Tire Pressure Monitoring Systems (TPMS) for essential information about tire health, but several common issues can hinder their effectiveness. One prevalent problem is sensor failures, which can occur due to battery depletion or damage from road debris. When sensors malfunction, they may fail to provide accurate readings, leading you to underestimate or overestimate tire pressure. Additionally, you might encounter false alerts, a common malfunction that can confuse your understanding of your tires’ actual condition. Environmental factors, like extreme temperatures, can also affect sensor performance. Ignoring these issues can compromise your vehicle’s safety and performance, so being aware of these common malfunctions is vital for maintaining ideal tire health.

Maintaining Your Tyre Pressure Monitoring System

While you might rely on your Tire Pressure Monitoring System (TPMS) for accurate tire pressure readings, regular maintenance is essential to confirm its reliability. To achieve peak performance, consider the following tyre pressure maintenance steps:

Reliance on your TPMS is important, but regular maintenance ensures its accuracy and reliability for optimal performance.

- Check sensor battery life regularly; low batteries can lead to inaccurate readings.

- Perform monitor calibration after tire changes or rotations to guarantee precision.

- Inspect the system for any physical damage or corrosion that could affect functionality.

Frequently Asked Questions

Can I Drive With a Malfunctioning Tyre Pressure Monitor?

You shouldn’t drive with a malfunctioning tyre pressure monitor. Safety concerns arise from inaccurate readings, increasing driving risks. Maintaining ideal tyre pressure is essential for safe, efficient driving, ensuring your freedom on the road isn’t compromised.

How Often Should I Check My Tyre Pressure Manually?

You should check your tyre pressure manually at least once a month. Curiously, under-inflated tyres can reduce fuel efficiency by 3%. Using pressure gauges regularly is crucial for ideal tyre maintenance and ensuring your driving freedom.

Do Tyre Pressure Monitors Require Battery Replacement?

Yes, tyre pressure monitors do require battery replacement. Typically, their battery lifespan ranges from five to ten years. Regular monitor maintenance guarantees peak performance, allowing you the freedom to drive confidently without worrying about tyre pressure.

Will Changing Tyres Affect the TPMS Calibration?

Yes, changing tyres can affect the TPMS calibration. It’s vital to guarantee proper tyre calibration for sensor accuracy. Any discrepancies may lead to incorrect readings, impacting your driving experience and potentially compromising safety.

Are Aftermarket Tyre Pressure Monitors Reliable?

Aftermarket tyre pressure monitors can be reliable, but you’ve got to take into account sensor accuracy. Their advantages include cost-effectiveness and customization, yet verify they’re compatible with your vehicle to maximize performance and avoid potential issues.